20

2020

-

09

The manufacturer of electric numerical control Screw press interprets the nuts of electric numerical control Screw press

The manufacturer of electric numerical control Screw press interprets the nuts of electric numerical control Screw press

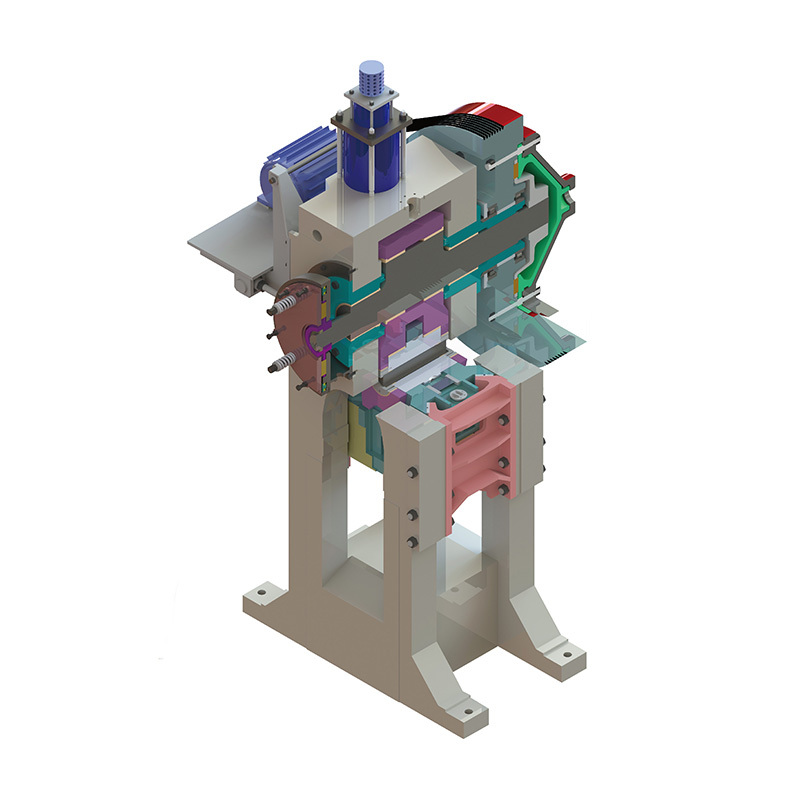

The nut is an important accessory of the electric Screw press. The electric Screw press includes a body, a support beam arranged on the body with large cylindrical holes, a drive motor fixed on one side of the support beam, a small belt pulley connected with the output end of the drive motor, and a large belt pulley connected with the small belt pulley through the belt, A shaft sleeve with a top fixed inner sleeve on the large belt pulley and a bottom end extending into the large cylindrical hole, a nut fixed inside the shaft sleeve, a screw embedded on the nut, and a slider fixed at the bottom of the screw.

Working principle of numerical control electric Screw press: it is a forging machine that uses screw and nut as transmission mechanism and uses screw transmission to transform the forward and reverse rotary motion of flywheel into the up and down reciprocating motion of slider. During operation, rotate the flywheel to accelerate its rotation to store energy, while pushing the slider downward through screws and nuts. When the sliding block contacts the workpiece, the flywheel is forced to decelerate to a complete stop, and the stored Rotational energy is converted into impact energy, which strikes the workpiece through the sliding block to deform it. After the blow is over, rotate the flywheel to reverse and drive the slider up to return to its original position.

Selection of Nut Material

The nuts produced by the electric numerical control Screw press factory are mainly made of ZCuZn25Al6Fe3Mn3, ZCuAl10Fe3 and HAL66-6-3-2, and can also be customized according to customer requirements. ZCuZn25Al6Fe3Mn3, with a copper content of about 65% and zinc content of about 24%. Aluminum can improve the strength, hardness, and corrosion resistance of brass. It has good plasticity and can withstand cold and hot working, but it is prone to medium temperature brittleness during Hot working such as forging. The specific temperature range varies with the content of Zn, generally between 200 and 700 ℃. Therefore, the temperature during Hot working should be higher than 700 ℃. ZCuAl10Fe3 cast copper alloy has high mechanical properties, good wear resistance and corrosion resistance, and can be welded without being easily brazed. ZCuAl10Fe3 cast copper alloy is used for important castings that require high strength, wear resistance, and corrosion resistance, such as shaft sleeves, nuts, worm gears, and pipe fittings working below 250 ℃.

Previous Page

.

Qingdao Minghui Metal Forming Machinery Co.,Ltd specializes in the production of J58A series electric CNC Screw press and FP/MP series hot die forging presses. The company has a strong technical force. Since its inception, the company has been adhering to the business philosophy of "responsibility, integrity and pragmatism", and has been forging ahead in business activities.

Qingdao Minghui Metal Forming Machinery Co.,Ltd

Address: Taiwan Industrial Park, Jiaozhou City, Qingdao, Shandong

E-mail: sales@qdmhjx.com

Contacts: Mr Wang

Phone: +86 18663977787

Fax: 86-0532-83281398

Address: Taiwan Industrial Park, Jiaozhou City, Qingdao, Shandong

E-mail: sales@qdmhjx.com

Contacts: Mr Wang

Phone: +86 18663977787

Fax: 86-0532-83281398

Copyright © 2023 Qingdao Minghui Metal Forming Machinery Co.,Ltd