J58A Electric CNC Screw Presses

Category:

Product Center

Keywords:

Summary:

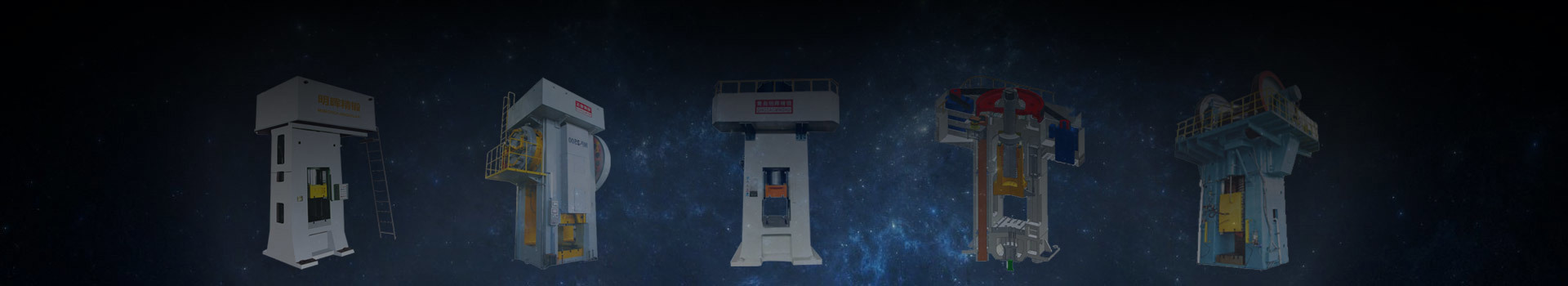

J58A Electric CNC Screw Presses

The J58A series electric CNC screw press has a reasonable structure, convenient operation, safe operation, efficient and energy-saving, high degree of automation, strong anti bias load ability, and can be forged at multiple stations. It is equipped with a core control system, abbreviated as PLC, to control the action of the executing mechanism, achieve precise control of the strike energy and the return stroke of the slider, accurately select the strike force and strike energy, and is equipped with a fault diagnosis system and overload alarm device, To ensure the correct, stable, and reliable accurate operation of the equipment, it is a new generation of excellent forging equipment.

Phone:

Product Details

Basic Parameters

| Model |

Nominal Force |

Motion part energy |

Ram stroke |

Min. mold height |

No. of Stroke |

Ram Bottom dimension |

Table dimension |

Main Motor Power |

Overall dimension |

Height above the ground |

|

J58A-160 |

1600 |

15 |

350 |

370 |

30 |

490x500 |

560x510 |

37 |

2380x |

3200 |

|

J58A-300 |

3000 |

30 |

380 |

400 |

28 |

650x500 |

650x570 |

45 |

2380x |

3600 |

|

J58A-400 |

4000 |

40 |

420 |

500 |

24 |

800x530 |

800x670 |

55 |

2800x |

4400 |

|

J58A-500 |

5000 |

60 |

440 |

500 |

24 |

850x540 |

850x680 |

75 |

2800x |

4600 |

|

J58A-630 |

6300 |

72 |

535 |

600 |

21 |

900x690 |

900x800 |

55+55 |

3600x |

5200 |

|

J58A-800 |

8000 |

100 |

545 |

630 |

21 |

950x750 |

950x850 |

75+75 |

3800x |

5400 |

|

J58A-1000 |

10000 |

140 |

560 |

660 |

17 |

1000x800 |

1000x900 |

90+90 |

4800x |

5600 |

|

J58A-1250 |

12500 |

160 |

580 |

660 |

17 |

1100x800 |

1100x950 |

110+110 |

4800x |

5800 |

|

J58A-1600 |

16000 |

280 |

650 |

800 |

15 |

1250x930 |

1250x1090 |

160+160 |

4800x |

6000 |

|

J58A-2000 |

20000 |

360 |

700 |

840 |

14 |

1350x1090 |

1350x1250 |

185+185 |

5200x |

6600 |

|

J58A-2500 |

25000 |

500 |

700 |

860 |

14 |

1450x1250 |

1450x1400 |

220+220 |

6000x |

7600 |

|

J58A-3150 |

31500 |

750 |

750 |

940 |

14 |

1600x1300 |

1600x1500 |

250+250 |

6400x |

9000 |

|

J58A-4000 |

40000 |

1000 |

750 |

1000 |

11 |

2200x1330 |

2200x1600 |

315+315 |

6200x |

9600 |

|

J58A-5000 |

50000 |

1300 |

800 |

1100 |

10 |

2200x1450 |

2200x1700 |

400+400 |

6800x |

9800 |

|

J58A-6300 |

63000 |

1600 |

850 |

1300 |

8 |

2200x1600 |

2200x1800 |

500+500 |

7200x |

10200 |

|

J58-8000 |

80000 |

2280 |

950 |

1450 |

8 |

2200x1640 |

2400x1900 |

315+315+ |

8200x |

12400 |

|

J58A-8000 |

80000 |

2280 |

950 |

1450 |

8 |

2200x1640 |

2400x1900 |

630+630 |

8200x |

12400 |

|

J58A-10000 |

100000 |

3600 |

1000 |

1600 |

7 |

2600x1940 |

2800x2200 |

710+710 |

9000x |

12800 |

|

J58A-12500 |

125000 |

5000 |

1100 |

1800 |

6 |

2900x2200 |

2900x2500 |

800+800 |

11000x |

13800 |

Structure of J58A series electric numerical control Screw press

The electric Screw press is composed of rack, flywheel, screw, balance cylinder, brake, jacking, air circuit, lubrication, electrical, platform and other components.

1. Rack: Adopting a split structure, the crossbeam, column, and base are fastened together by four pull rods to form a closed frame structure. The pull rod resultant force meets the setting of equipment parameters, and the Factor of safety is set.

2. Flywheel: The flywheel consists of a central sleeve and a large pulley. Connect the large pulley with the small pulley on the main motor and rotate clockwise and counterclockwise. Drive the screw to rotate through the central sleeve inner spline, thereby driving the slider to perform linear motion and output energy. Soft transmission, good rebound force, and protection of the screw and transmission device. Our company adopts belt transmission method for all products below 2500 tons.

3. Platform: The platform is a closed structure surrounded by a flywheel cover. Install components such as the main motor, flywheel brake, and air box inside the platform.

4. Screw: The screw is connected to the center sleeve through an upper spline, and there is a boss in the middle that transmits the forging force to the bed through a thrust bearing. When the screw works, it only rotates and does not move axially. The nut drives the slider to complete the forging.

5. Braking: The braking is full stroke braking. The clamping function and braking function of the electric motor ensure that the slider stops at the top dead center and does not slide down. Dual braking device, fully ensuring the safety of operators and equipment.

6. Slider: The upper part of the slider is a cylindrical guide rail, equipped with copper nuts inside, and the lower part is an X-shaped guide rail. The wedge shaped adjustment block can accurately adjust the clearance of the guide rail, and the clearance of the diagonal guide rail is equal. The X-shaped guide rail is supplied with independent lubrication oil. The cylindrical guide rail is immersed in the lubricating oil in the large cavity of the bed.

7. Balance cylinder: Two balance cylinders are located on the front and rear sides of the bed. After the slider is forged, the motor reverses and the balance cylinder assists the slider in returning to the top dead center to complete a cycle.

8. Top material: There is a top rod installed in the center of the workbench, which is usually in the lowest position.

9. Air pipeline: The operating power of the press is compressed air, and the minimum air pressure introduced from the workshop pipeline is not less than 0.5Mpa. The shut-off valve is the main switch of the air pipeline.

10. Lubrication: the machine consists of oil tank, lubricating motor, gear oil pump, oil suction filter, overflow valve, German Harvey plunger pump, etc., forming an independent closed lubrication system. Provide centralized lubrication for friction surfaces with heavy workload.

11. Safety protection

There are emergency stop switches on the control box panel and at the entrance of the maintenance platform, equipped with adjustment and automatic buttons. When adjusting and replacing the mold, pressing the adjustment button can achieve inching. The top surface of the equipment has a closed platform, which is not only used for maintenance and use, but also to prevent accidents caused by bolts loosening and falling off in the event of long-term failure.

Electrical Configuration of J58A Series Electric CNC Screw press

1. Electrical control system

The electrical control system adopts the internationally advanced programmable logic controller (PLC) produced by Siemens as the main control element to realize the real-time control of the whole machine; Siemens human-machine interface (HMI touch screen) is used to achieve information exchange between operators and machines. The main motor is a switched reluctance motor, which has the ability to quickly start and change speed, and can achieve high-precision programmed speed control. Combined with the use of microcomputer controlled KSC20 series drivers, the machine can meet the requirements of various workpiece forging processes.

2. Main control components

This machine uses the module (PLC) produced by Siemens in Germany as the main control element to control all actions. High reliability, rich control instructions, and extremely strong real-time characteristics. Its application field completely replaces traditional relay control, covering all industrial and civilian fields related to automatic detection and control, meeting the requirements of advanced users. In this machine, Siemens PLC mainly controls various functions of the entire machine and monitors the operation of the machine in real-time. The machine has two working modes: adjustment and automatic. In the adjustment mode, interlocking between machine modes can be achieved through the upward and downward movements of the slider, thereby achieving jog and ensuring the safety and reliability of machine actions. PLC detects various signals during the operation of the entire machine, controls the machine to perform relevant actions and promptly alarms to protect the normal operation of operators and the machine tool.

3. Human Machine Interface (HMI)

The human-machine interface is mainly responsible for setting and modifying parameters such as the operator's impact force on the machine, displaying relevant data and faults during machine operation. Provide relevant assistance information such as the working status of the main motor, lubrication status of the machine, top material, etc., and provide troubleshooting methods. Convenient for operators and maintenance personnel to control and maintain the machine.

4. Drive system of the main motor

This drive system is a high-tech speed regulation product developed based on modern microelectronics technology, digital technology, power electronics technology, and modern control theory. The controller is composed of embedded microprocessors, large-scale integrated circuits, power electronic power devices, and control software, and adopts various control methods for efficiency optimization. The circuit board adopts multi-layer board surface mounting technology, with strong anti-interference ability, and has two given modes of speed and torque, meeting various action requirements of forging equipment. The control system can be configured with interfaces for connecting to other equipment according to the requirements of the production line, in order to facilitate the formation of a highly automated forging production line.

5. Switched reluctance motor

The rotor of a switched reluctance motor is composed of convex silicon steel sheets, with a simple structure, durability, long service life, and convenient maintenance; High starting torque and low current, suitable for frequent starting and forward and reverse rotation, and can quickly change the speed, achieving high-precision programmed speed control. It has shorter starting time, higher starting torque, lower starting current, higher power factor, and obvious energy-saving effect compared to variable frequency motors. So far, it is the most suitable domestic motor for electric Screw press.

Related Products

Related Products

.

Qingdao Minghui Metal Forming Machinery Co.,Ltd specializes in the production of J58A series electric CNC Screw press and FP/MP series hot die forging presses. The company has a strong technical force. Since its inception, the company has been adhering to the business philosophy of "responsibility, integrity and pragmatism", and has been forging ahead in business activities.

Qingdao Minghui Metal Forming Machinery Co.,Ltd

Address: Taiwan Industrial Park, Jiaozhou City, Qingdao, Shandong

E-mail: sales@qdmhjx.com

Contacts: Mr Wang

Phone: +86 18663977787

Fax: 86-0532-83281398

Address: Taiwan Industrial Park, Jiaozhou City, Qingdao, Shandong

E-mail: sales@qdmhjx.com

Contacts: Mr Wang

Phone: +86 18663977787

Fax: 86-0532-83281398

Copyright © 2023 Qingdao Minghui Metal Forming Machinery Co.,Ltd