04

2020

-

12

How to reasonably set the forging temperature range?

How to reasonably set the forging temperature range?

Ferrocarbon alloy

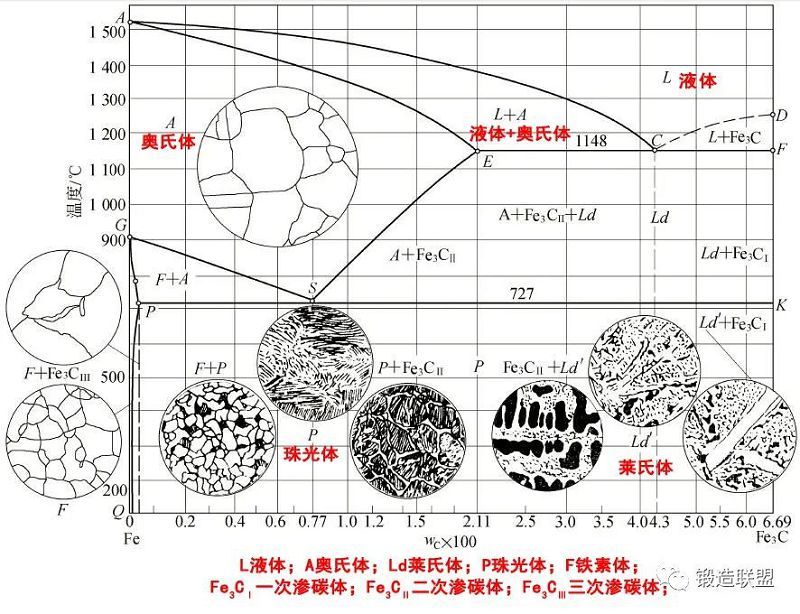

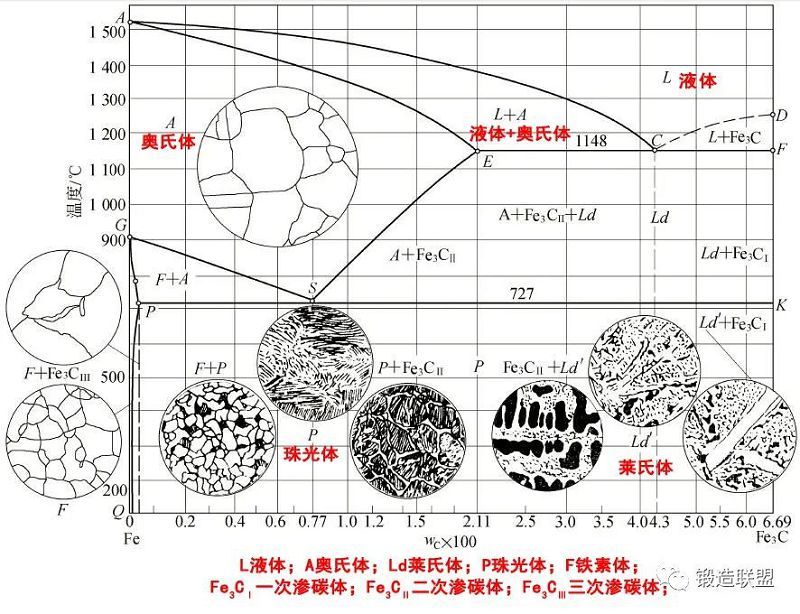

Phase diagram of Fe-C alloy

1 Forging temperature range

definition

The forging temperature range refers to the temperature range between the starting forging temperature (initial forging temperature) and the ending forging temperature (final forging temperature).

How to reasonably set the forging temperature range?

principle

To ensure that the metal has high plasticity and low deformation resistance within this temperature range, and can obtain appropriate metallographic structure and mechanical properties with the least number of fires.

supplement

♠ The initial forging temperature should ensure that there is sufficient plasticity of the metal before final forging, and the metal can still obtain recrystallized structure after forging;

♥ Excessive final forging temperature not only increases energy consumption, but also causes the grains of the forging to continue to grow during the cooling process, thereby reducing its mechanical properties, especially impact toughness.

♣ If the final forging temperature is lower than the recrystallization temperature, work hardening will occur inside the forging billet, reducing plasticity, sharply increasing deformation resistance, and generating large residual stress internally, leading to cracking of the billet during forging or subsequent processes. Therefore, the final forging temperature is generally 50-100 ° C higher than the recrystallization temperature of the metal.

3. Forging temperature range of carbon steel

Based on

It can be determined based on the iron carbon phase diagram.

characteristic

♠ The initial forging temperature of carbon steel decreases with the increase of carbon content;

♥ The initial forging temperature of alloy steel can generally be determined by referring to carbon steel with the same carbon content, and the initial forging temperature of alloy steel decreases more with the increase of carbon content.

supplement

♠ When steel ingots solidify in liquid state, their original grain structure is relatively stable and there is a small tendency for over burning. Therefore, the initial forging temperature of steel ingots can be 20-50 ℃ higher than that of billets and steels of the same steel grade;

♥ The billet exhibits good plasticity in the high-temperature single-phase zone (such as the austenite zone above the GSE line). Therefore, hypoeutectoid steel is generally forged at around 15-50 ℃ above the GS line.

♣ Low carbon steel (carbon content ω C<0.3%), due to its presence in the two-phase zone below the GS line( α+γ) There is also sufficient shaping, so the final forging temperature can be below the GS line. Lower temperatures can enhance the strength of materials through dislocation strengthening during severe deformation, while also enhancing the strength of materials through fine grain strengthening of partially recrystallized ferrite without reducing toughness.

♦ In hypereutectoid steel, the temperature drops below the SE line and secondary carbides begin to precipitate along the grain boundaries. In order to break these cementites, the two phase zone below the AE line can be further forged, and the forging process can be stopped before the deformation of the forging billet is significantly reduced. The final forging temperature of hypereutectoid steel should generally be above 50-100 ℃ above the SE 'line.

4. Forging temperature range of other materials

Comprehensive determination

The forging temperature range of non-ferrous metals, stainless steel, high-temperature alloys, and steel grades that do not undergo phase transformation (such as austenitic steel and ferrite steel) needs to be determined through various tests, as well as comprehensive analysis of metallographic diagrams, plasticity diagrams, resistance diagrams, and recrystallization diagrams, to ultimately determine the reasonable forging temperature range.

supplement

♠ In general, if the carbon content of steel is within 5 ‰, the forging temperature range is 1250-800 ° C; For those with a carbon content greater than 5 ‰, the forging temperature range is 1200~850C °;

♥ The forging temperature range of ordinary carbon steel is 1300~700 C °, while the forging temperature range of high-quality carbon steel is 1250~800 C °; The forging temperature range of alloy structural steel is 1200~800 C °, and that of carbon Tool steel is 1150~750 C °; The forging temperature range of alloy Tool steel is 1150~800 C °, that of high-speed Tool steel is 1150~900 C °, that of stainless and acid resistant steel is 1200~750 C °, that of heat resistant steel is 1150~800 C °, that of spring steel is 1150~800 C °, and that of alloy structural steel is 1100~800 C.

♥ The forging temperature range of high-temperature alloys is 1150-850 ° C for iron based alloys and 1160-950 ° C for nickel based alloys.

♦ The forging temperature range of non-ferrous metals: zinc 165-110 ° C, brass 850-650 ° C, bronze 850-650 ° C, white copper 1120-700 ° C, pure copper 950-800 ° C, industrial pure aluminum 470-380 ° C, rust proof aluminum 450-380 ° C, hard aluminum 470-380 ° C, forged aluminum 480-380 ° C, superhard aluminum 450-380 ° C, and magnesium alloy 430-300 ° C.

Previous Page

Next Page

Previous Page

Next Page

.

Qingdao Minghui Metal Forming Machinery Co.,Ltd specializes in the production of J58A series electric CNC Screw press and FP/MP series hot die forging presses. The company has a strong technical force. Since its inception, the company has been adhering to the business philosophy of "responsibility, integrity and pragmatism", and has been forging ahead in business activities.

Qingdao Minghui Metal Forming Machinery Co.,Ltd

Address: Taiwan Industrial Park, Jiaozhou City, Qingdao, Shandong

E-mail: sales@qdmhjx.com

Contacts: Mr Wang

Phone: +86 18663977787

Fax: 86-0532-83281398

Address: Taiwan Industrial Park, Jiaozhou City, Qingdao, Shandong

E-mail: sales@qdmhjx.com

Contacts: Mr Wang

Phone: +86 18663977787

Fax: 86-0532-83281398

Copyright © 2023 Qingdao Minghui Metal Forming Machinery Co.,Ltd